If you’ve been thinking about a yacht installation, you’ll already know it has to deal with multiple issues, including:

- Shading from the rig

- Heat build-up

- Low light conditions

- Restricted space

- Curved surfaces

- Durability / walk on capability

- Weight

Solar technology is evolving and the solution arrived at with Julian is currently towards the leading edge, without getting into unproven territory.

MiPV Solar Panels

After investigating many solar panel technologies and brands we settled on CIGS (Copper Indium Gallium Selenide) thin film technology by a British manufacturer, MiPV (and, by the way, we didn’t get a special deal – this isn’t an ad!). The technology differs from conventional crystalline based solar photovoltaic systems and seems to have real advantages for yachts. Check their website https://mipvsolarpanels.co.uk for full details.

Perhaps the most useful thing I can add is an assessment of how these panels deal with the typical yacht installation issues:

Shading from the rig

Definitely one of the greatest challenges and it results in the output from many systems being dramatically below their theoretical maximum.

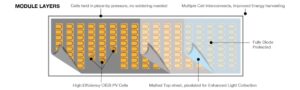

Solar panels comprise a grid of multiple cells and if a panel is built, for example, with just one diode per row of cells (a common configuration), when one cell is shaded the output from the whole row is cut off. Worse, if there is only one diode on the whole panel (not unheard of), then any shading shuts down the whole panel! Panels with multiple diodes are quite rare – and usually expensive.

The MiPV panels have a diode on every pair of cells so, if a panel is affected by shade, then only the output from the actually shaded cells is lost – the others keep working. This makes it possible to maximise the panel coverage on, for example, the roof – and just accept that some cells will get shaded. We’re not worried that some cells will be shaded by lines routed directly to the cockpit – it’s better to cover the roof with panels so that those losses are more than compensated elsewhere. If we’re anchored for a while and want to maximise the output, we can tidy lines away from the cells and swing the boom out to a shroud.

Heat build-up

It’s a huge irony that the output of most solar panels drops dramatically as they get hotter in the sun! Talk about Catch 22… The problem is particularly acute on cabin roof installations – davit mounted arrays fare better due to airflow underneath. There are ways to reduce the problem somewhat (eg. bonding panels onto hollow plastic sheets) but this adds weight and cost while impairing robustness.

CIGS thin film technology, however, is completely unaffected by temperature (within the range the solar panels will face) so their potential output remains at maximum. Major advantage.

Low light

The MiPV panel’s output curve rises significantly faster in lower light conditions than conventional panels so they produce more power at the ends of the day (which happen twice every day) and on cloudy days (which seem to happen more often than we’d like!).

Restricted space

The downside to the CIGS thin film technology is that the theoretical maximum output per square metre is lower than the most efficient conventional panels.

This, however, ignores the facts that their performance doesn’t decrease with heat and their output is better in low light. Overall, therefore, we believe the MiPV panels will score well, even though the theoretical max output figure for an array area will appear lower than some.

MiPV manufacture the panels to order, with a choice of three widths (358mm/3 cells – 674mm/6 cells – 990mm/9 cells) and almost any length.

It’s therefore possible to tailor the array to maximise the space available and to suit desired cable run locations.

Curved roof capability

These thin film panels are genuinely flexible – in fact they’re supplied rolled! So there’s is no problem fitting them on a curved surface, such as the flowing line of the CM’s roof although the curve, of course, can only be in one plane.

Durability

CIGS thin film technology has no glass in the construction, unlike crystalline semi-flexible panels which surprisingly (to me anyway) have a thin glass layer. That’s why they tend to break down over time (even during transportation and installation if not handled carefully), lose efficiency, often have a relatively short warranty period and most can’t be walked on.

MiPV panel durability means they have a 25 year / 80% output warranty and it’s perfectly OK to walk on them. That’s a big deal in maintaining ongoing output, coupled with elimination of the cost and hassle of replacing them.

Weight

The panels weigh about 3kg/m2, so they’re very light and thin compared to most. If you’re going to create a truly light boat it’s essential to focus on weight in every aspect of the build and fit-out, as CM do.

MPPT charge controllers and cabling

A smart MPPT harvests the energy from solar panels efficiently and routes it to the boat’s battery bank. Our system will use Victron SmartSolar charge controller MPPTs, matching most of our electrical components. If weight, cost and cabling were no object, then you’d connect each panel to an individual MPPT charge controller. It’s normal, however, to balance those three factors and connect two or three panels, often more, into one MPPT – we’ll have six panels and three MPPTs.

BUT – and here’s something that’s easy to overlook – if you connect different size/output panels (or panels that get shaded differently – eg on either side of the boat) into one MPPT, then you reduce the output dramatically. In the case of different size panels, you may even reduce the output of each panel to less than that of the smallest one! It’s important to design the panel layout with this in mind – connect equal size panels – connect panels from the same part of the array.

The wide variety of MiPV panel sizes helped make it possible to design an effective layout, taking into account the above restrictions.

Installation size and location

Our original plan was to install panels on the cabin roof and over the davits but, since choosing the MiPV system, we’ve decided not to fit the davits array. We’ll save weight at the aft end of the boat and maintain an unobstructed view.

The CM’s roof will comfortably fit a 2kW array which, bearing in mind the panel’s shading and low light efficiencies should, we reckon, be ideal for our systems. The Watt & Sea will add hydrogeneration when we’re sailing, so we’ll have more than enough power underway. If there does prove to be a shortfall at anchor we could add a couple more “roving” MiPV panels clipped onto, say, the trampolines – and stow them rolled up on passage.

Cost

Despite all the apparent advantages of the MiPV panels, they’re competitively priced – OK, more expensive than the cheapest rigid or semi flexible panels – but less than most high quality options.

Aesthetics

And finally… they have a smart all-black appearance!